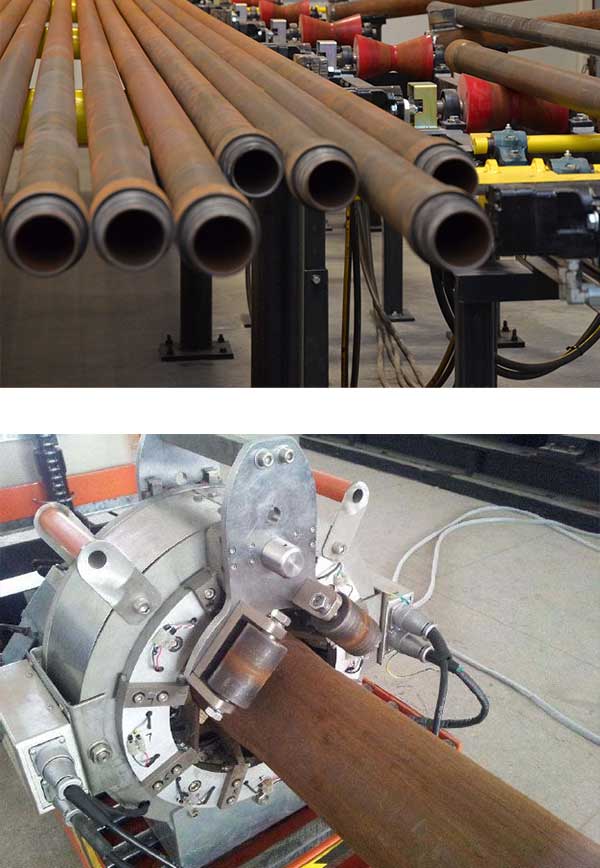

TUBULAR INSPECTION

Service Details

Drill Pipe

Drill inspection is executed as per customer-nominated standards, using case-appropriate techniques.

Electromagnetic Inspection (EMI) units are utilized at intervals guided

by drilling conditions and past failure experiences.

A.C. Yoke Magnetic Flow technique is used for most inspections, while sandblasting units are employed to prepare inspection surfaces.

Bottom Hole Assembly

A well-maintained bottom-hole assembly supports a high drilling performance.

We conduct BHA inspections as per API RP7, DS1, NS2, or other standards as nominated by the commissioning clients.

Tubing / Casing

From a visual inspection of the body (and thread) to identify external damage, to full-length drifting of the tubular structures, all are performed by us.

Additionally, maintenance services, namely cleaning, coating, hardness-testing, thread-gauging, and ultrasonic wall-thickness measurement are conducted by our technicians.

Specialty Tools

We provide technological support for directional drilling, casing drilling, and bore-hole enlargement.

These are capably combined with the flexibility of seismic-guided drilling

services to deliver efficiencies in the areas of utility-construction and slant drilling.

Services includes but not limited:

- Pipe inspections to DS1 3rd Edition CAT1-CAT5

- Pipe Inspections to API RP7-G & NS1/NS2

- Inspection of Drill Pipe, Heavy weight, Drill collars, Subs & Cross Overs

- Full length API drifting

- BHA (Bottom Hole Assembly)

- ID & OD dimensional checks

- Hardness testing

- Full EMI scanning

- Portable connection re-facing

- MPI / DPI / UT inspections

- High Pressure external & internal cleaning